- Home

- About Us

- Products

- PSA Nitrogen Gas Generator

- PSA Oxygen Gas Plant

- PSA Hydrogen Gas Plant

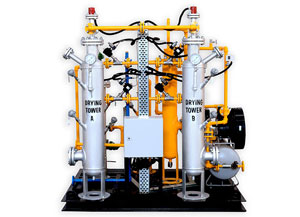

- Desiccant Air Dryer

- Liquid Solvent Dryer

- Nitrogen De-Oxo Plant

- Ammonia Cracker

- Pressure Vessels

- Green H2 And Cracked Ammonia Hydrogen Generation

- Activated Alumina

- Carbon Molecular Sieve (CMS)

- Dew Point Sensor

- Oxygen Analyser

- Nickel Catalyst

- Contact Us

- Inquiry

- Career